BioPod Container

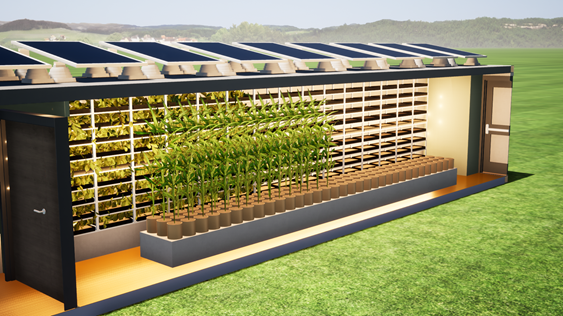

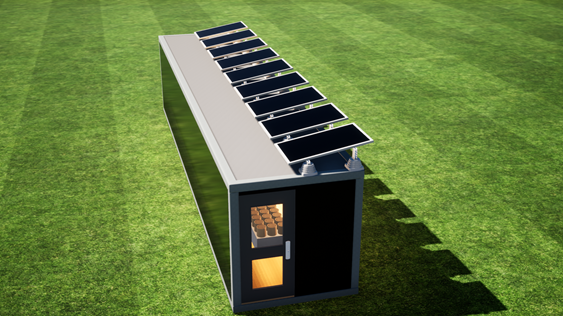

Biopod is a closed-loop vegetable production system for producing organic salat, microgreen, tomato, chili, cucumbers etc., using renewable energy and surface/rainwater. The Biopod uses renewable energy from solar cells, for its electricital consumption, and from heat pump for heating/cooling of the BioPod. We call the Biopod an off the grid solution.

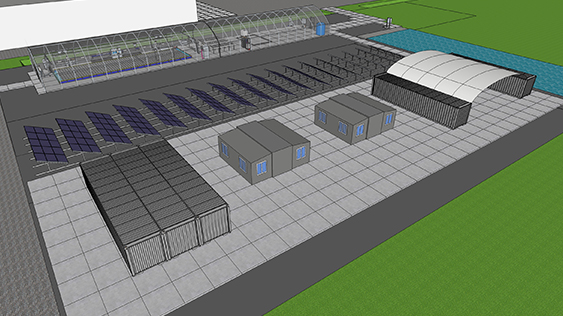

The BioPod solution is a closed-loop food production, operating on a household- or a community level, and integrated as a new urban farm concept of Eco villages and Industrial agro food parks.

Biopod container 1.0.

Contact information: Anders Thomsen, ant@nordicflexhouse.dk

Biopod container 2.0.

Contact information: Anders Thomsen, ant@nordicflexhouse.dk

Biopod fish container.

Contact information: Anders Thomsen, ant@nordicflexhouse.dk

BioPod Container

Biopod is a closed-loop vegetable production system for producing organic salat, microgreen, tomato, chili, cucumbers etc., using renewable energy and surface/rainwater. The Biopod uses renewable energy from solar cells, for its electricital consumption, and from heat pump for heating/cooling of the BioPod. We call the Biopod an off the grid solution.

The BioPod solution is a closed-loop food production, operating on a household- or a community level, and integrated as a new urban farm concept of Eco villages and Industrial agro food parks.

Biopod container 1.0. Contact information: Anders Thomsen, ant@nordicflexhouse.dk

The core of BioPod technologies is an integration of Aquaponics/Hydroponics and Vermiponics in a climate control system, rainwater harvesting and water preservation system, and an energy supply system.

Value proposition

- High yield of vegetable/micro green and saves a lot of land and labor

- 95% circulation of water

- 100% renewable energy (PV, heat pump with ventilation)

- Vegetable: Salat, microgreens, tomato, chili and bell pepper

- Cost effective (28 time more effective compared to field and 80% saving in labor cost) and reduced carbon foot print (farm to table)

- Organic waste to nutrients and energy

- Healthy indoor climate

- A single person can maintain and plant/harvest at this plant, with approximately 1-2 hours of effort each day. ROI: 4 years.

- The use of indoor vertical agriculture (like our BioPod container) is growing globally by 24% annually. The market is expected to reach $6.4 billion by 2023.

Value proposition

- High yield of vegetable/micro green and saves a lot of land and labor

- 95% circulation of water

- 100% renewable energy (PV, heat pump with ventilation)

- Vegetable: Salat, microgreens, tomato, chili and bell pepper

- Cost effective (28 time more effective compared to field and 80% saving in labor cost) and reduced carbon foot print (farm to table)

- Organic waste to nutrients and energy

- Healthy indoor climate

- A single person can maintain and plant/harvest at this plant, with approximately 1-2 hours of effort each day. ROI: 4 years.

- The use of indoor vertical agriculture (like our BioPod container) is growing globally by 24% annually. The market is expected to reach $6.4 billion by 2023.

The core of BioPod technologies is an integration of Aquaponics/Hydroponics and Vermiponics in a climate control system, rainwater harvesting and water preservation system, and an energy supply system.

Target groups

We create value to:

Restaurants by recycling and reuse the organic waste and supply local produced and healthy vegetable with reduced waste to the restaurants and their customers.

Municipality by recycling and reuse the organic waste in the city.

Eco village with the BioPod as a shared resource facility to be used by the residents. The Eco village can also sell the produced vegetables to surrounding cities, and thereby create a business for the community.

Developer or real estates, that deliver green apartment projects or refurbishment to existing apartments in cities. The BioPod will be established on the roof as shared resource facility for the residents (food cities).

SDG Tech Award 2020 nominee

SDG Tech Award 2023 finalist

BioPod Container in Skive

The performance of the BioPod container is demonstrated in Skive, that produces vegetables through soilless cultivation. Depending on the customer demands, the container can be constructed as a combination or a single solution of the modules below:

- Salad in a Moving Gutter System (MGS)

- Cucumber in buckets

- Tomatoes in buckets

BioPod Container in Skive

The performance of the BioPod container is demonstrated in Skive, that produces vegetables through soilless cultivation. Depending on the customer demands, the container can be constructed as a combination or a single solution of the modules below:

- Salad in a Moving Gutter System (MGS)

- Cucumber in buckets

- Tomatoes in buckets

Photos from the BioPod container in Skive. Click to enlarge.

Leasing agreement

It is possible to lease the BioPod container with 5 up to 10 years payback time and without the need of down payment.

Life cycle assessment

To ensure and document the environmental benefits of the BioPod container, a life cycle assessment (LCA) has been performed in Skive.

One 40f BioPod container produces 1,680 kg of tomatoes and cucumbers or 12,373 kg of salad per year.

The overall results indicate environmental benefits and climate change mitigation when the selected vegetables are cucumbers, tomatoes or lettuce.

Economic assessment

An integral part of sustainable development is the economic viability of the systems taking part in the innovative urban farm solutions. The BioPod container consists a long-term, scalable solution for vegetable production with an expected lifetime of 20 years. The revenues of the container are sourced by the sales of vegetables while as expenses are considered both the capital and operational costs.

The BioPod container is assessed for its potential to perform economically viable under the three scenarios of vegetable production. The three scenarios are:

- Tomatoes in buckets

- Cucumbers in buckets

- Salad in the MGS (Moving Gutter System)

The economic viability assessment of the system is performed with the Net Present Value (NPV) method. The NPV method can indicate to a potential investor whether a project is worth investing in or if depositing money at a bank (or alternative investment) is a more rational choice.

The capital investment is considered to occur in Year 0 while the operational costs and revenues start occurring after Year 1 and a period of 20 years.

The scenario of salads grown in the MGS system presents a profitable investment. It is worth mentioning, that the BioPod container has a flexible growth design, which can be modified according to the demands. Thus, if the container was designed for the salads, tomatoes and cucumbers to occupy 50%, 25% and 25% of the available area in the container can be a highly profitable investment.

We also have BioPod installed in a Tiny house in Odder: www.petersholm.com

We are exporting the BioPod solution to China and India, through our local partners. In India it is the Govardhan Eco Village and in China it is the World Green Design Organization.

User Interface

Visualization of the user interface for the Biopod container on mobile and desktop. Click to enlarge.

Please login to see more visualization.

Partner and collaborators

Anders Thomsen, CEO, Nordicflexhouse ApS is project manager of the BioPod container and market responsible in Nordic, Europe and Asia.

Hydrovertic ApS is our production partner for constructing the BioPod containers.

Other project Partners: Consibio, Niqo systems,

The BioPod container was originally awarded by the VIDA project and has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement nº 777795 and the GUDP.

Dealer agreement with Retail360 for delivery of Biopod container 2.0 to Greenland, Denmark, Sweden, Norway and the Faroe Islands focusing on the retail sector. The BioPod container 2.0 is an optimized Biopod container for producing tomatoes, cucumbers, herbs, lettuce etc. We can produce 22698 lettuce a year in the Biopod container 2.0.